Mechanical Durability

Making sure your device is durable is one of the most basic goals for every mechanical engineer. In the electronics industry we move fast and this puts a lot of pressure on the traditional design-prototype-test process. With simulation we can predict the durability. This helps you save money on prototypes and speed up your development time.

Below is a small selection of simulations that have benefited our customers.

Snap fit/connector insertion simulations

Snap fits and connector designs can be tricky. We need to balance the usability of the snap with durability and strength.

In our snap fit and connector simulations we can predict the insertion force, stress, deformation and durability of the system. Best of all, these are pretty basic nonlinear contact models they they are accurate and runs very fast.

Press fit simulations

Interference fit and press fits are great ways to bond different parts together. However how strong is the press fit and how durable are the components?

Small features in the model can cause undesirable stress concentrations reducing the durability of the device.

A simulation will quickly predict the force, stress and durability of these parts.

Seal and water leakage

Many devices need to be water proof or at least water resistant. Using advanced nonlinear contact capabilities, we can simulate the closure process and the seal/gasket behavior.

This type of analysis help engineers determine the right trade off between clamping force, seal effectiveness and durability.

Test to failure

What does it take for a device to fail? How does it fail? Some times we really need to know these things to comply with codes and regulations.

Simulation is a much faster and cheaper way to predict failure. In addition simulation provides a way to iterate on the design quickly without spending tens of thousands of dollars on models and machining.

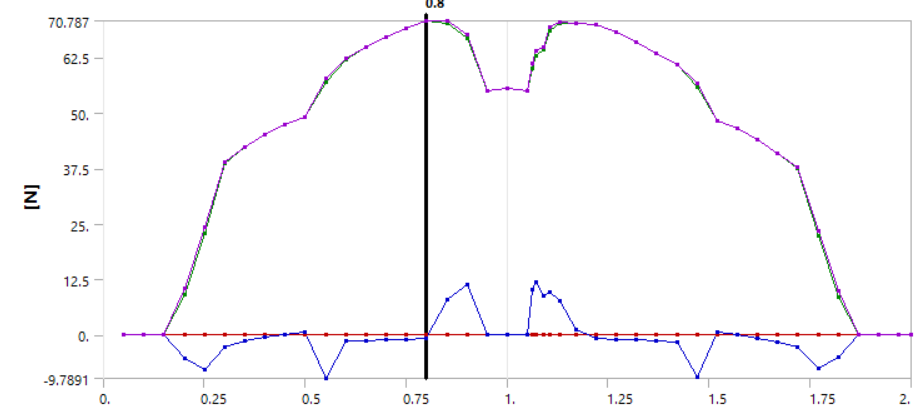

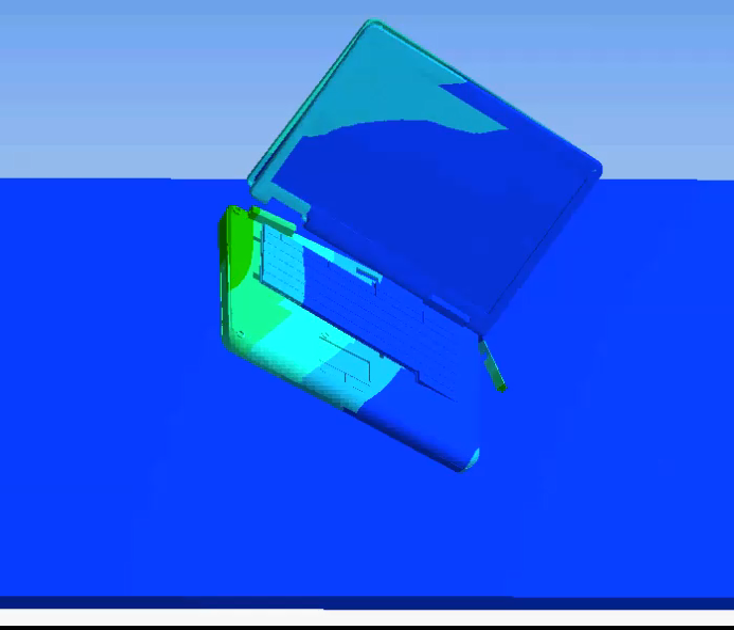

drop simulation

System level drop analysis is unparalleled in terms of providing insight and confidence into the design. Although time consuming, system level drop analyses are used by all major mobile electronics companies to ensure and improve drop tolerance of modern mobile electronics.

We provide a full suite of solutions to balance the time and accuracy of drop simulation so that our customers get the results they need in the time they have.

Ball Impact

User interface devices need to withstand impacts. It is common to perform ball impact tests to characterize impact resistance.

Simulation allows you to characterize and design an impact resistant display stack so that your prototypes will survive these tests. This helps the development process to proceed smoothly and get your product to market faster.

This is but a small selection of our capabilities. We are able to tackle almost any mechanical simulations worth doing. If this is of interest to you please contact us.