Drop Reliability

Drop and impact are the most common failure modes for mobile devices. Build durability into your design and ensure it passes your drop test by simulating throughout your design process.

There are various methods that can be ideally used at different points during the design process. We help you understand your options and find the best choice to fit into your workflow.

Cell phone drop simulation

Full Fidelity Drop simulation

Model impact in various directions at various heights. These analyses give you an accurate prediction of what happens during a drop event on all of your important components. The key challenge is to set up a simulation efficiently such that the simulation finishes quickly. These simulations require expertise and are a good option for engineers or teams focused on drop reliability.

JEDEC component drop standard

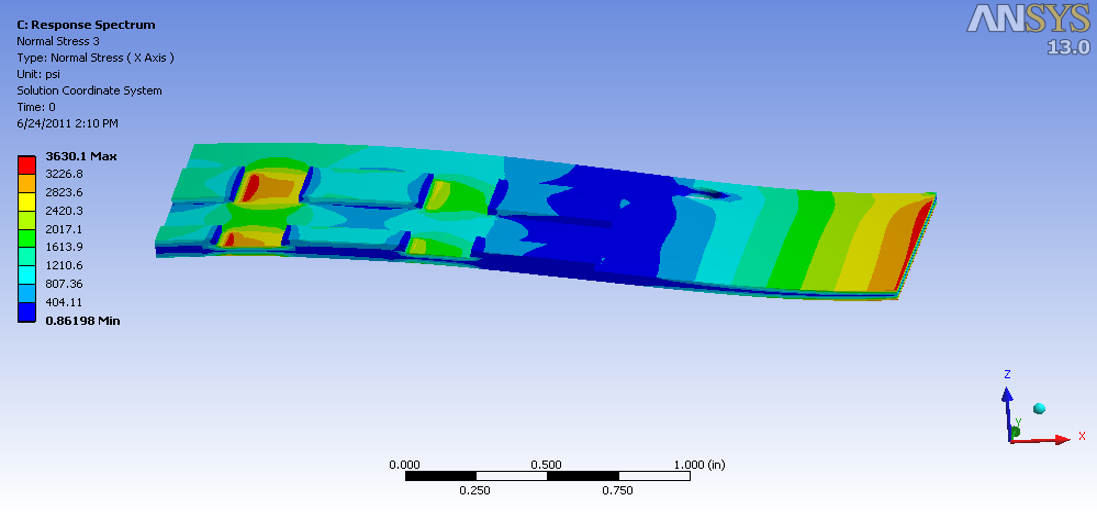

Component level drop simulation

Reduce simulation complexity by reducing the scope of your analysis. If your concern revolves around a few components (PCB, Camera, Screen, etc.), we can greatly simplify the complexity of the analysis.

By carefully making responsible assumptions, these simulations become fast and easy to apply throughout the design process for designers and engineers that have to juggle various responsibilities.

PCB shock response

Linear Shock response

Use simple and quick checks to understand max deflections and stress in subcomponents.

These are very fast and simple analyses. Used responsibly, they can help all engineers design more robust components that withstand the stress of impact.